OFFSHORE POWER APPLICATIONS

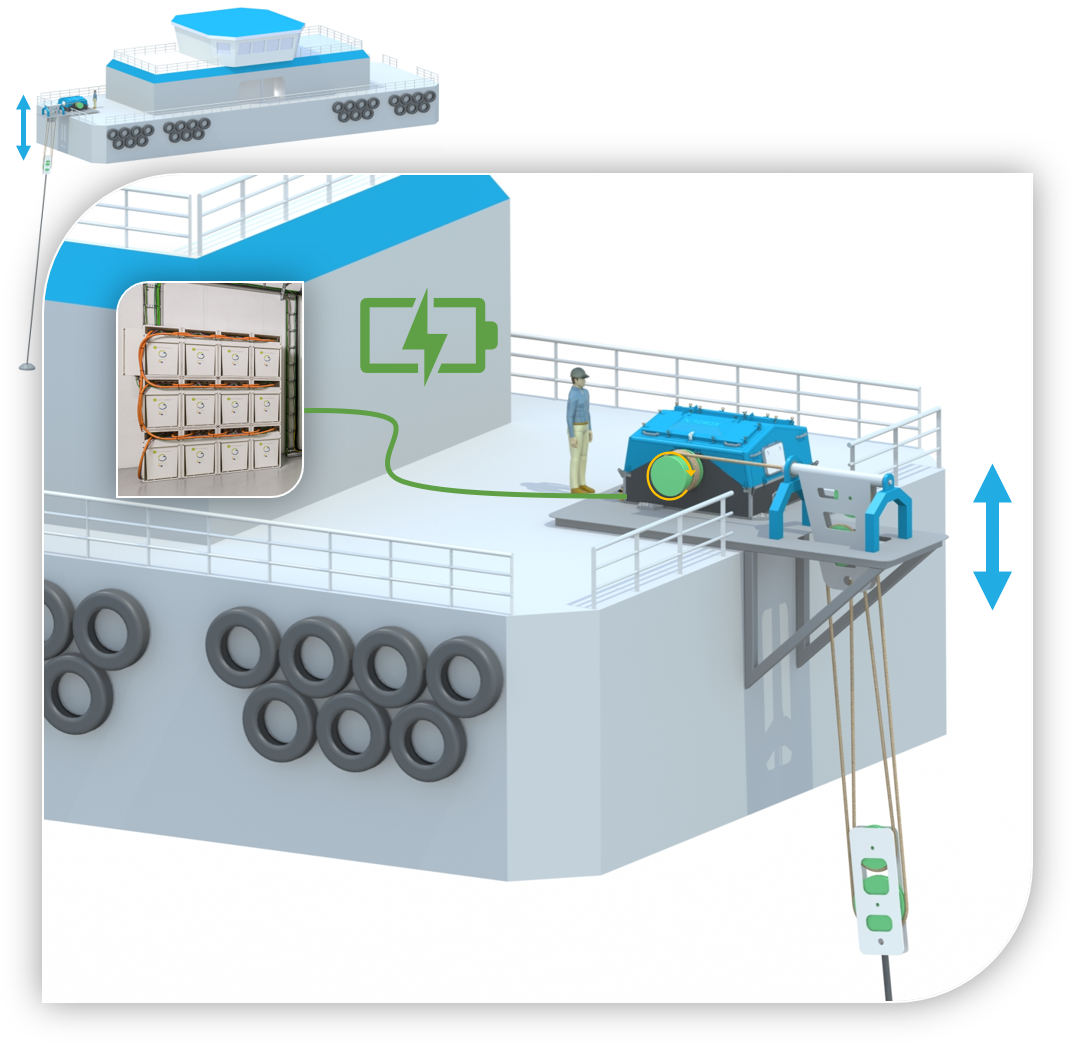

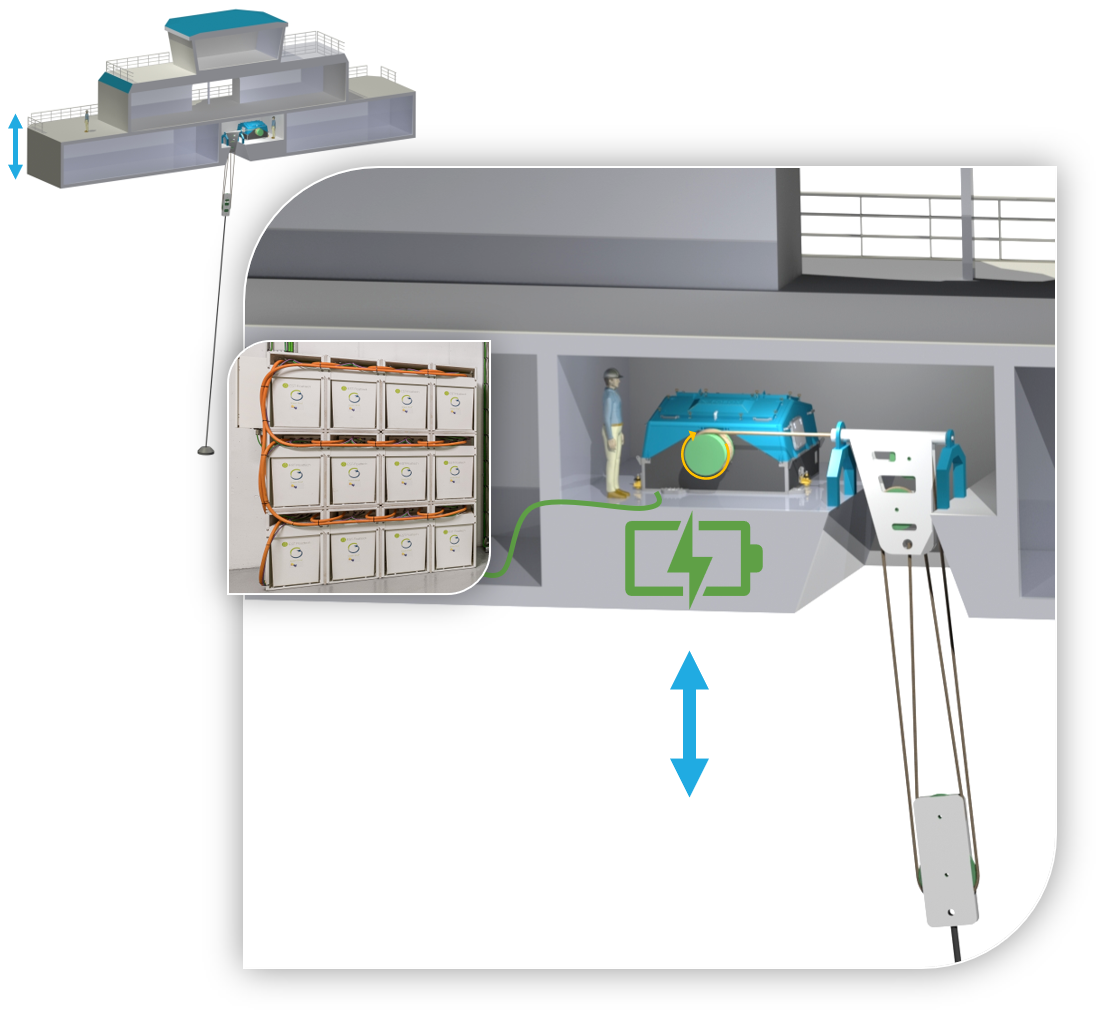

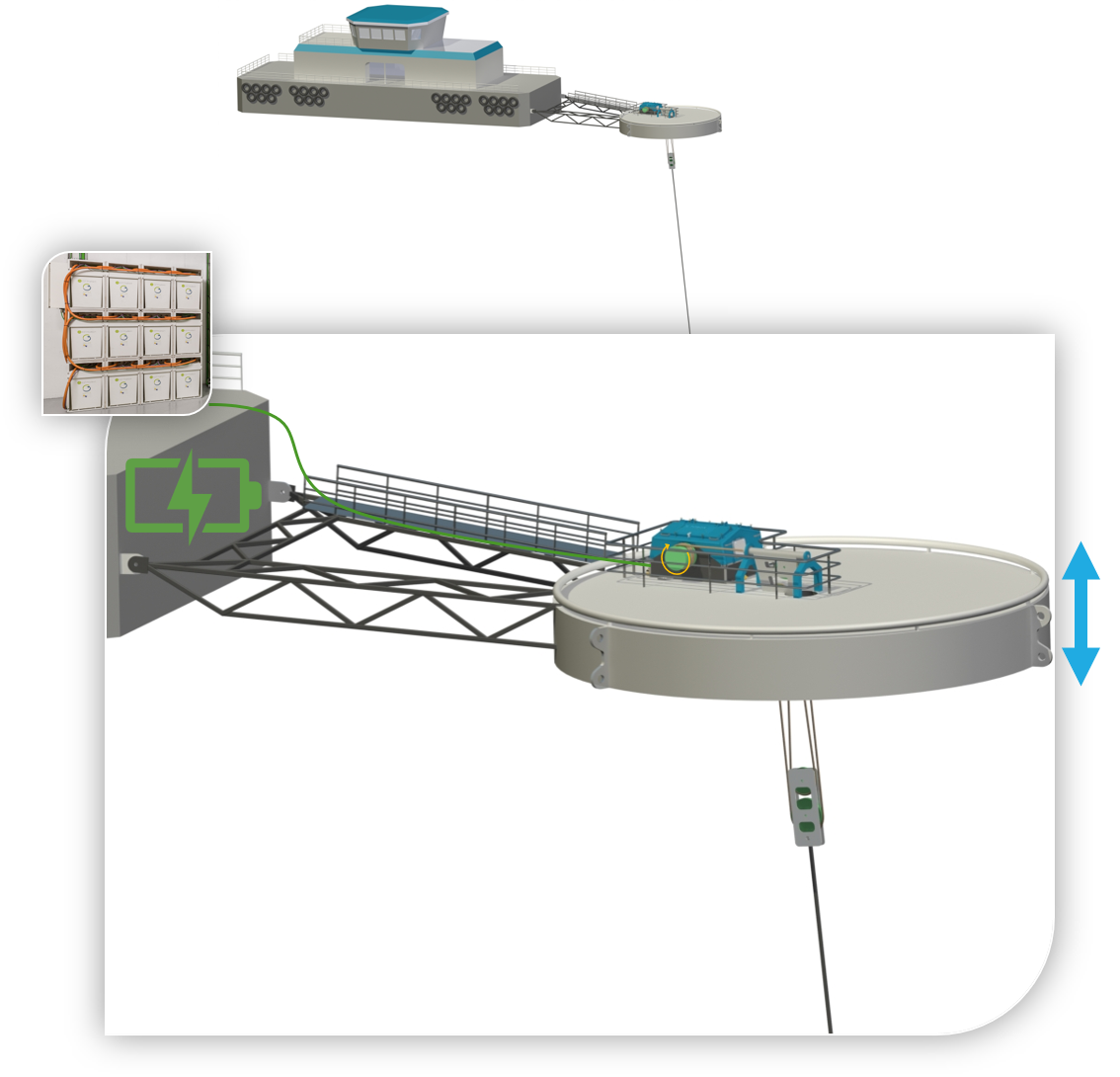

POWER GENERATION FOR HYBRID FEED BARGES

An increasing number of aquaculture sites are being developed further from shore in more exposed locations, where feed barges cannot feasibly get power from shore. Diesel generators have been the go-to solution for the industry, but a number of suppliers are now offering integrated battery packs to reduce generator run time and, hence, diesel consume.

BOLT Sea Power’s wave power take-off winch unit can be installed directly on the feed barge and generate electricity to charge the batteries, by damping the motion of the barge. The PTO is dimensioned according to the size and power consum of the barge, and generates 5-50kW, depending on sea states, further reducing run time of the diesel generator, while also damping motion of the barge.

Retrofit to existing feed barges:

Integrate into new builds:

PTO and float hinged to barge:

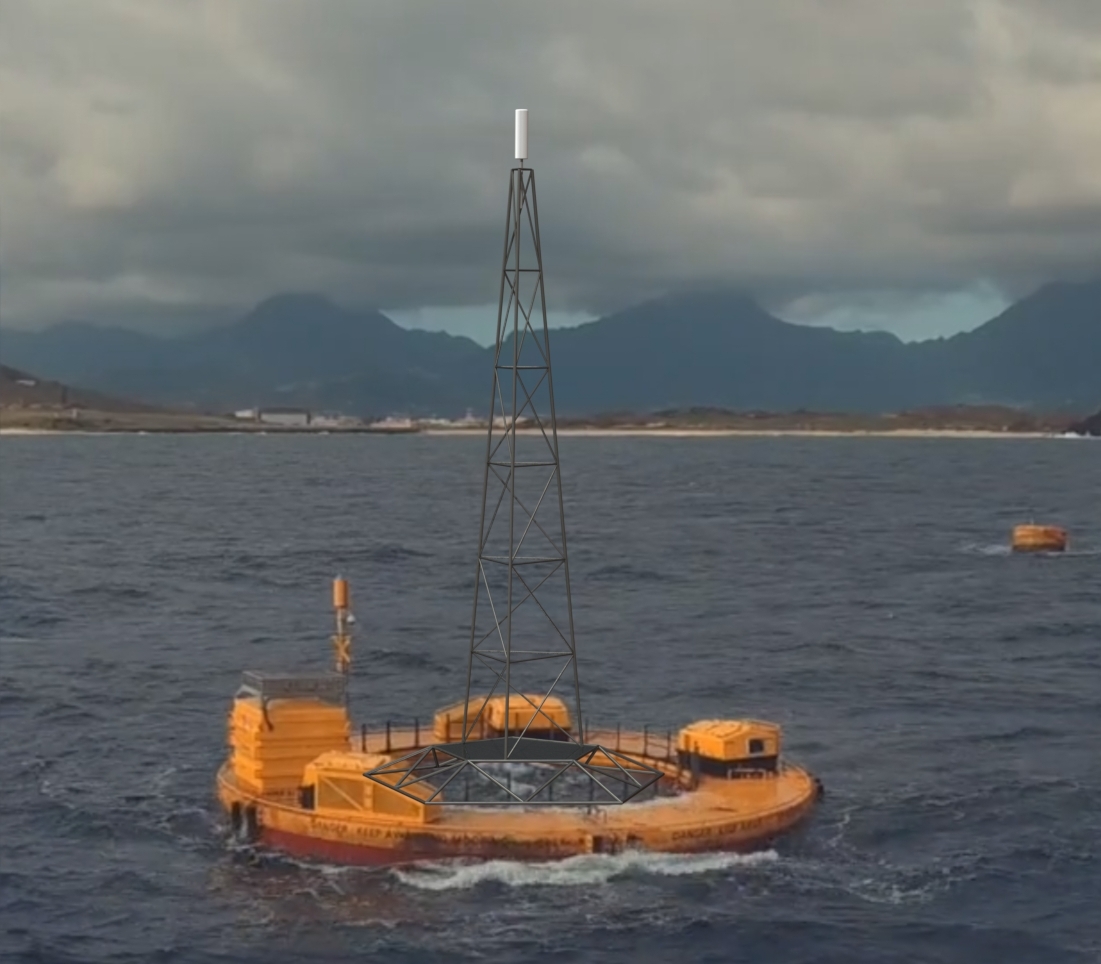

FLOATING, STAND-ALONE OFFSHORE LTE MASTS

As 4G/LTE wireless coverage offshore are rapidly being developed, the offshore industry are increasinly relying on LTE for communication offshore. However, as base stations traditionally needs a platform to be mounted on. Combined with the final range achieved with a given base station antenna, causes black holes in the coverage.

A BOLT Sea Power multi-PTO buoy can host LTE antennas in a floating mast up to 40m, while powering switches and network equipment on ocean waves, creating a flexible, stand-alone floating antenna solution. This can be used to receive a subsea optical fiber cable and create a base station, or to extend the range of an existing base station.

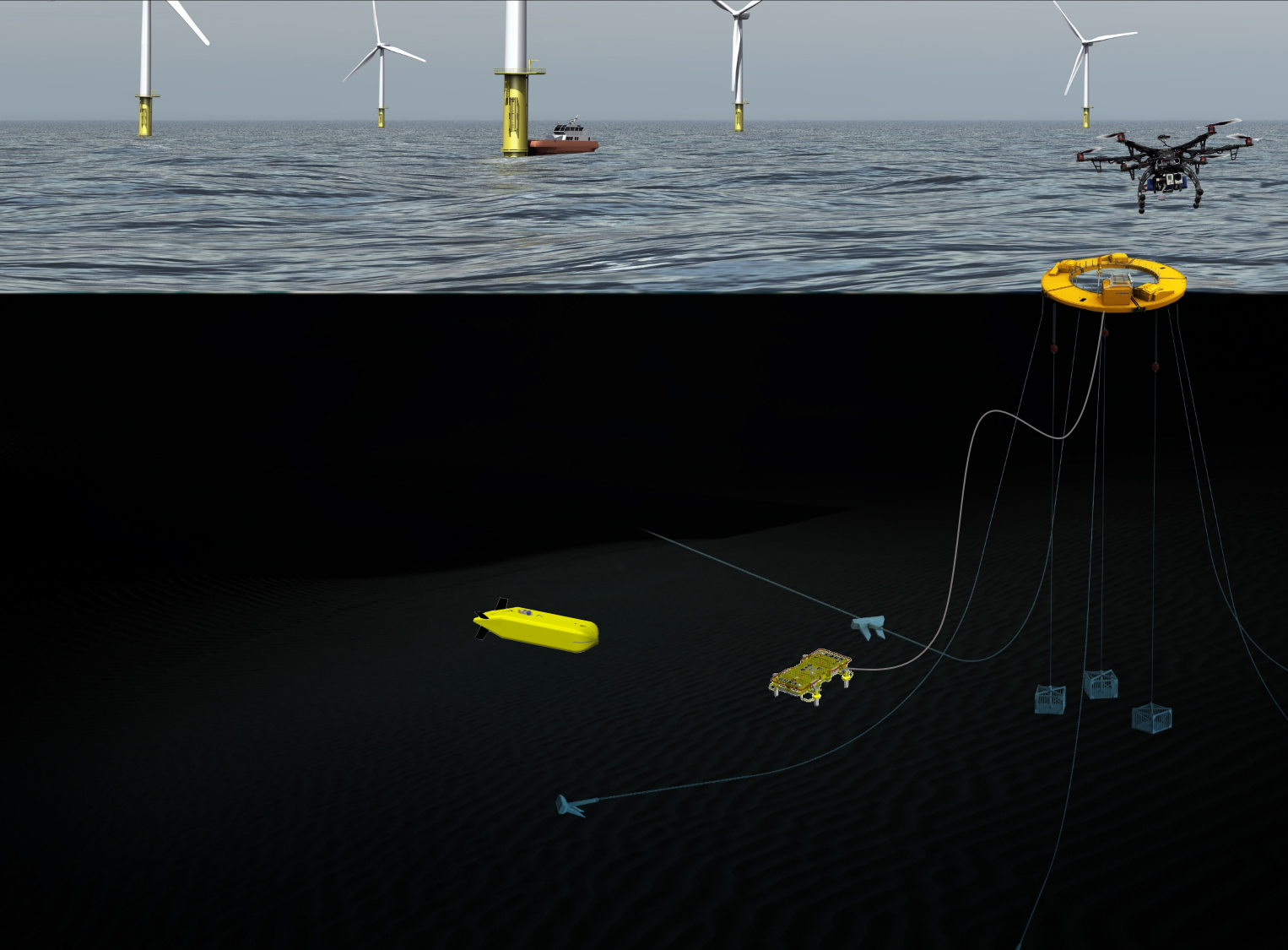

OFFSHORE WIND INSPECTION DRONES

Today, the vast majority of topside inspection of offshore wind turbine are done with aerial drones, operated by pilots who are brought on site by vessels, relying on calm weather.

A BOLT Sea Power buoy can be fitted with drones at port, towed out during spring time, installed in the middle of the wind park and left over the summer months. Due to the buoy’s ability to provide power for communication equipment and for wireless charging of the drones, inspection can be done remotely from shore whenever the weather is calm, significantly reducing cost of vessel and increasing flexibility of inspection.

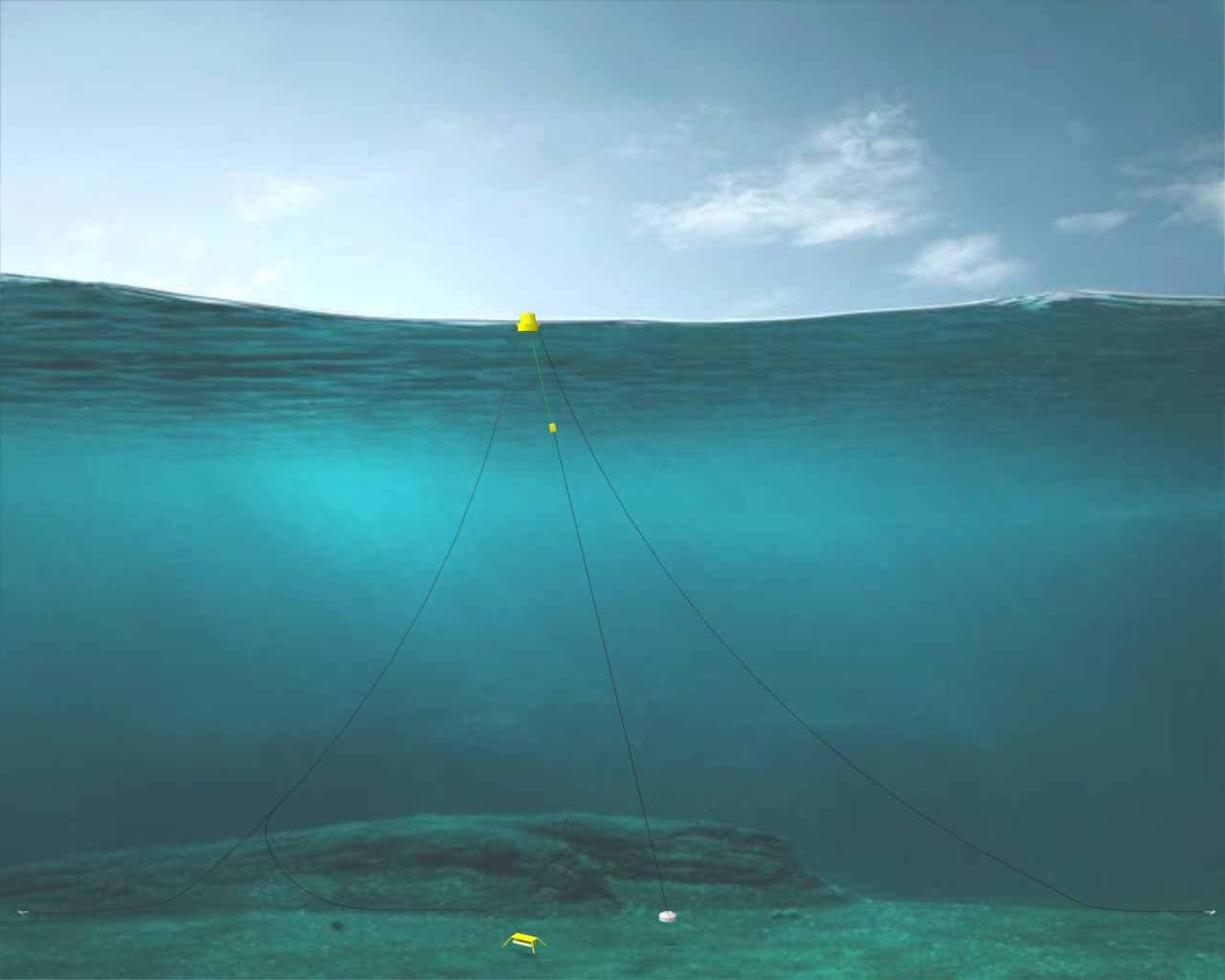

SUBSEA POWER

Across a variety of offshore industries, there is a push to reduce vessel hours and offshore man hours to reduce cost, risk and weather dependency. Reduced cost of battery capacity and increased 4G and satellite communication infrastructure opens up the opportunity to operate systems located offshore, remotely from shore. In addition to reduced cost and risk, an adaptation to remote operation can greatly increase utilization of equipment, providing for 24/7 availability, during all weather conditions.

For systems consuming an average of 200W or less, power supply in the form of battery packs in combination with PV panels, can provide for sufficient uptime and availability. However, offshore operators are looking to deploy more conventional systems offshore for resident, autonomous operation, prompting the need for high power energy supply, a reliable, low latency and high capacity communication link to shore, as well as cost efficient installation methods.

POWER DOWN – COMMUNICATION UP

BOLT Sea Power develops offshore power units that delivers all three capabilities. Our onboard winch provides for power production, station keeping and power transfer subsea. The winch, already operated as a heave compensated anchor system, also has the inherent capability to install equipment on the sea floor, allowing for a cost efficient installation method.

POWER AND COMS FOR UNDERWATER INSPECTION DRONES DOCKS

Most offshore industries have adapted to the use of ROVs and AUVs for inspection, maintenance and repair work. Traditionally operated from vessels hovering above, it makes for a vessel- and labor intensive operation that is also sensitive to weather. To reduce cost, there is a drive to adapt operations to use of underwater inspection drones (UIDs) with docking stations located subsea to allow UIDs to recharge and communicate to shore. A number of industry players are developing these drone docks and several field tests are underway at this point. However, the need for power and communication infrastructure puts a constrain on where docks can be located.

A power unit from BOLT Sea Power will feed power for battery charging and provide a communication link to shore, enabling true and unconstrained remote operation regardless of available infrastructure.

Based on the more than 40.000 hour of offshore operation of our BOLT Lifesaver power buoy, Fred. Olsen Ltd. is currently configuring a product where we fit one Power Take-Off winch to a 5m diameter buoy. At 8-13tons weight, it allows for fast install and recovery and provides power and communication subsea at any depths for up to 12 months without maintenance.